FAQ Polycarbonate Multiwall Sheets

Multiwall panels, also called multiwall sheets, are a type of building panel made from polycarbonate or other plastics. They are characterised by a honeycomb or tunnel structure that gives them extra stability and strength. The sheets are lightweight, durable and have good insulating properties.

Multiwall sheets are often used outdoors for roofing, glazing or facades, such as on patio roofs, covered parking spaces, conservatories, greenhouses or as partition walls. They are available in various sizes, thicknesses and colours depending on requirements.

The panels protect against the effects of weather such as rain, snow and hail. They can also filter ultraviolet radiation to protect plants and people from harmful UV rays. Multiwall sheets are a practical and cost-effective solution for many building applications.

Several types of multiwall panels are suitable for building a greenhouse, patio roof or conservatory, as they are both translucent and insulating. The most commonly used materials for multiwall sheets are polycarbonate and acrylic (also known as Plexiglass). At Exolon Group, we make our multiwall panels from polycarbonate.

The benefits of polycarbonate multiwall sheets:

- High resistance to impacts and breakage, providing perfect protection from wind and weather

- UV protection

- Good thermal insulation

- Lightweight

- Aesthetically pleasing

- Easy to handle

- Durable and available in various thicknesses and structures (geometries), e.g. twinwall sheets, triplewall sheets, X-structure sheets

- Fire protection classification according to EN 13501-1

When it comes to finding the right multiwall sheets for a greenhouse, there are various factors to consider. These include climate and budget, as well as the desired translucency and thermal insulation. Multiwall polycarbonate sheets are the ideal choice here. Their high impact resistance, translucency and good thermal insulation (depending on the sheet type) make them a very popular choice for greenhouses, especially in areas with frequent snow or strong winds.

Multiwall polycarbonate sheets are available in a variety of colours, thicknesses and finishes to suit different requirements.

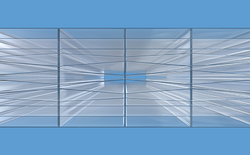

The main difference between tunnel structured multiwall sheets or multiwall sheets with a geometry is the number and structure of air chambers in the sheets. These differences affect the sheets’ thermal insulation, translucency and strength.

The Exolon® multi UV multiwall panel range offers different geometry types for specific applications, such as those with high thermal insulation. The sheets are available in clear transparent, opal white or coloured. Their versatility makes them suitable for a wide range of glazing and roofing projects. From conservatories to verandas and canopies to greenhouses; from skylights and barrel vaults to sports halls and stadiums.

Twinwall sheets. Twinwall polycarbonate sheets have a multi-layered structure with two parallel walls that form separate air chambers within the sheets. Twinwall sheets offer better thermal insulation and strength compared to single-wall sheets. The additional air chambers help to reduce heat loss and increase the impact resistance of the sheets.

Twinwall sheets. Twinwall polycarbonate sheets have a multi-layered structure with two parallel walls that form separate air chambers within the sheets. Twinwall sheets offer better thermal insulation and strength compared to single-wall sheets. The additional air chambers help to reduce heat loss and increase the impact resistance of the sheets.

Multiwall sheets. They feature three or more parallel walls that form several separate air chambers within the sheets, depending on the type. They offer thermal insulation, strength and impact resistance than twinwall sheets. The additional air chambers further improve the sheets’ insulation performance and stability. The sheets are easy to process and cold bend and are used in applications like strip lighting in industrial halls.

The HX or X geometry offers increased load-bearing capacity, while its higher stiffness prevents bending due to snow loa ds, for example. This is an essential safety aspect for demanding roof coverings. The HX multiwall panel is suitable for all private and industrial applications that require high thermal insulation. These include verandas, canopies, conservatories, roofs, industrial halls and many more. This is guaranteed by the innovative geometry: a complex and effective combination of walls and air chambers. This leads to a demonstrable increase in the sheet’s insulation properties, while maintaining its light weight and mechanical properties. Due to their geometry, they are primarily installed flat and should not be bent in cold.

ds, for example. This is an essential safety aspect for demanding roof coverings. The HX multiwall panel is suitable for all private and industrial applications that require high thermal insulation. These include verandas, canopies, conservatories, roofs, industrial halls and many more. This is guaranteed by the innovative geometry: a complex and effective combination of walls and air chambers. This leads to a demonstrable increase in the sheet’s insulation properties, while maintaining its light weight and mechanical properties. Due to their geometry, they are primarily installed flat and should not be bent in cold.

When selecting the right type of multiwall sheet, you should consider the intended use, the desired thermal insulation and translucency, and the necessary strength. Standard Twinwall sheets are suitable for basic applications. multiwall panels with a tunnel structure are primarily used for strip lighting in industrial halls due to their easy processing and cold bending properties. Sheets with a complex structure are more suitable for applications that call for higher insulation and strength, such as conservatories, greenhouses or patio covers.

In order to cut multiwall panels for greenhouses, patio roofs or conservatories to size, there are a few points you should bear in mind. Multiwall polycarbonate sheets are relatively easy to cut with the right tools and precautions.

Here are the steps for cutting your panels properly and safely:

1. Preparation:

- Place the polycarbonate multiwall panel on a flat, clean and stable surface to prevent it from slipping or scratching.

- Wear protective goggles and gloves to avoid injury.

- Measure and mark the cut line on the panel’s protective film with a pencil or waterproof pen and a rail or ruler.

2. Tools:

- Choose the right tool for the material and thickness of the multiwall polycarbonate sheet. For thin sheets you can use a cutter knife, while a

- jigsaw, circular saw or chop saw with a fine-toothed blade (for plastics) is more suitable for thicker sheets.

3. Cutting:

- If using a cutter knife, score the cutting line several times along the marking with the cutter knife until you have reached a sufficient depth.

- Be careful not to score too deeply to avoid breaking the polycarbonate multiwall sheet. Carefully break the sheet along the inscribed line by

- applying pressure to the edge.

- If using a saw, guide the saw along the marked cutting line, taking care to saw slowly and evenly to achieve a clean cut. If necessary, use a guide

- rail to ensure the accuracy of the cut.

4. Finishing:

- Deburr the cut edges with sandpaper or a file to remove sharp edges and achieve a clean finish.

- Be careful not to remove the protective film until the work is complete and the sheet is installed.

- Please note that multiwall panels can be sensitive to vibration and pressure. Be sure to apply an even force during cutting and support the sheet well to avoid splintering or breaking the material.

Water can collect in multiwall sheets if they are not installed or sealed correctly, or if they have been damaged.

Here are some possible causes of water penetration in multiwall panels:

- Incorrect installation. If the sheets are not installed or aligned correctly, water can enter through the open edges or joints. Make sure that sheets are properly aligned and the ribs are vertical so that water can drain away.

- Insufficient sealing. Insufficient sealing of the edges and joints of multiwall sheets can cause water to penetrate. Use suitable sealing materials such as aluminium clamping profiles, sealing tapes or silicone to seal the edges and joints, and prevent water from penetrating.

- Damage to the sheets. Cracks, holes or other damage to the multiwall sheets can cause water to penetrate. Inspect the sheets regularly for damage and replace damaged sheets as necessary to prevent water penetration.

- Condensation. Condensation can sometimes form inside the multiwall panels, especially in the event of extreme temperature fluctuations or high humidity. Although this is not the same as water penetration from the outside, it can still lead to moisture in the sheets. Make sure that the sheets are installed correctly and that the edges and joints are well sealed to minimise the risk of condensation.

There are various materials and methods that can be used to seal multiwall polycarbonate sheets to prevent water, dirt and insects from entering.

Here are some common sealing materials and methods:

- Sealing tapes. Weatherproof, self-adhesive sealing tapes like aluminium tape can be used to seal the edges and joints of the multiwall sheets. Make sure that the sealing tape is UV resistant and suitable for outdoor use.

- Anti-dust tape (also known as ventilation tape). This special tape is applied to the open edges of the multiwall panels to prevent dirt and dust from entering, while still allowing some ventilation. This helps to reduce condensation in the sheets and prevent water penetration.

- Aluminium clamping profiles. These profiles are used to securely hold and seal the edges of the multiwall polycarbonate sheets. They are available in various shapes and sizes to fit the sheets’ structure.

- Silicone. Silicone sealant can be used to seal the transition between the profile and the sheet after the profiles have been fitted. Make sure to use a UV-resistant and neutral cross-linking silicone sealant suitable for outdoor use. Apply the sealant evenly along the joints and edges and smooth it with a spatula or fingers moistened with soapy water.

When using waterproofing materials and methods for multiwall sheets, it is important to select the correct materials for the specific application and sheet type, and to follow the manufacturer's instructions to ensure an effective seal.

Whether you use multiwall panels on patio roofing, conservatories or greenhouses, you can clean your polycarbonate sheets effectively with mild detergents and soft cleaning utensils without damaging the surface.

Here are some tips for cleaning multiwall polycarbonate sheets safely and gently:

- Remove coarse dirt and debris. Before you start cleaning, remove any loose dirt, leaves or debris from the surface of the multiwall sheets to avoid scratches during the cleaning process. Use a soft brush or broom for this purpose.

- Prepare the cleaning solution. Mix a mild, non-abrasive cleaner (e.g. a mild washing-up liquid, soap or a special plastic cleaner) with water in a bucket. Avoid aggressive cleaning agents or solvents that could damage the sheet surface.

- Clean the sheets. Dip a soft sponge or cloth into the cleaning solution and gently wipe the surface of the multiwall panels. Be sure to rinse the sponge or rag regularly to remove dirt and debris, and avoid scratching.

- Rinse the multiwall sheets thoroughly with water to remove detergent and dirt. Use a garden hose or bucket of clean water to rinse the multiwall polycarbonate sheets.

- Dry. Allow the sheets to air dry or use a soft, lint-free cloth to gently wipe the surface dry.

- Stubborn stains. For stubborn stains or deposits, you can use a soft brush or cloth together with the cleaning solution. However, avoid using abrasive cleaners or brushes with hard bristles, which could scratch the sheet surface.

Be sure to clean at moderate temperatures and out of direct sunlight to stop the cleaning solution from evaporating rapidly and prevent any damage to the sheets.

The hail resistance of multiwall sheets depends on the material and thickness. Multiwall polycarbonate sheets are known for their high impact strength and break resistance, which usually makes them hail resistant. Polycarbonate is a very tough and flexible material that can absorb the impact of hailstones better than some other materials such as glass or acrylic. It is therefore ideal for patio roof sheets, as well as conservatory and greenhouse multiwall sheets.

It is important to note that the hail resistance of multiwall polycarbonate sheets also depends on their thickness and quality. Thicker sheets generally provide better protection against hail and other impact loads.

If you need hail resistance, multiwall polycarbonate panels are a good option due to their higher impact resistance and break strength. Be sure to choose sheets of sufficient thickness and quality to ensure the best possible protection.

Versatile, functional, excellent. Exolon® multi UV makes creative building projects possible. From greenhouses to complex dome structures, experience the full range of design possibilities. The Exolon® multi UV range offers a variety of thicknesses, geometries, colours and structures suitable for building projects of almost any size.